Provide customers with filling production line and one-stop service that integrades advanced Chinese aseptic beverage filling technology.

Get a Quote

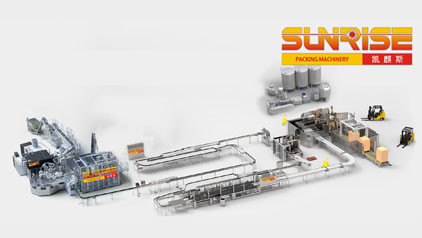

Maximize productivity and flexibility Sunrise aseptic production line is suitable for juice, tea, sports drinks, milk, yogurt and milk-based beverages.

Free Quote

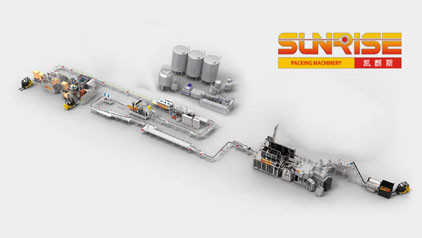

Smaller footprint, faster play and maximum flexibility. Sunrise aseptic production line is suitable for juice, tea, sports drinks, milk, yogurt and milk-based beverages.

Free Quote

Aseptic line Product Assessment:

Packaging an aseptic beverage means considering every variable which will influence its viability, and designing a package which will preserve your beverage's original profile. With help from Sunrise Intelligent scientific experts in beverage, packaging and industrial design early within the process, your production bottle can safeguard beverage integrity.

Benefits

Preform packaging design:

From preform and packaging design to final production and beyond, we assist you create a PET bottle that protects your product, delights your customers and strengthens your brand.

Benefit

Our fully integrated solution adopts the processing equipment and capabilities of the international processing system-Sunrise Intelligent Aseptic Technology.supported years of technological innovation that prioritises hygienic compliance and food safety while still taking under consideration your need for max uptime, our systems optimise aseptic production with efficient solutions designed to guard your beverage from preparation to filling.

Benefits

Dry Preform Decontamination

Sunrise aseptic filling system, scientifically proven aseptic dry preform decontamination

The Sunrise aseptic filling system decontaminates a preform instead of an entire bottle as this is an easier and safer method. Hydrogen peroxide (H202) is injected in the preforms before the oven so the heating phase activates the H202. This results in a high level of decontamination up to Log 6 with minimal residue. This decontamination system has been successfully implemented in many customer plants around the world. The unique, patented process ensures full production sterility and food safety, and the competitive solution ensures process simplicity and flexibility while lowering your total cost of ownership.

Safe and straightforward aseptic production:

After the aseptic filling process, the beverage product moves onto one among its most defining features - the label. Whether you need roll-fed or sleeve labels for your aseptic filled beverages, our labellers can handle any label format and can confirm your product stands out from the gang.

Higher labelling performance and efficiency

Once sensitive beverage product has been filled and therefore the bottle has been labelled, the first package is transferred using conveyors to its secondary packaging process. the ultimate result's the package the customer sees at the purpose of sale, so it must grab their attention. These packs ensure protection from elements like weather, pressure and temperature changes.

Whether you select shrink-printed film, nested packs or wraparound cartons, packers gently feed bottles to make sure durable and cost-effective packs.

Benefit

Once your packaged product is prepared to continue across the availability chain, efficiency during storage and transport is important . As bottles and packs vary in format and size, it's important that conveying and palletising handles a spread of products, packs and layer patterns.

Benefit

Our services cover all industries and reach all parts of the world.We can make all kinds of products for you according to your design.