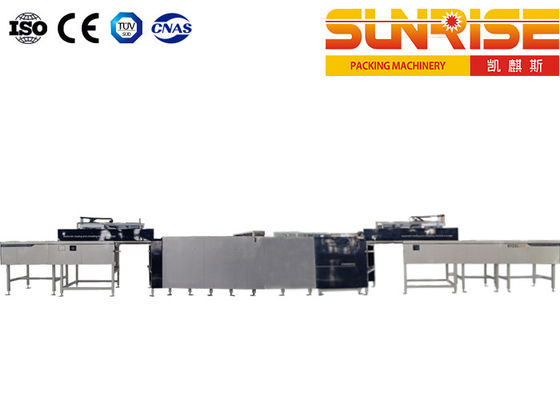

Durable Retort Loading And Unloading Cage Machine For Tin Can In Production Line

Product Description:

Products are transported by the conveyor, and products will be arranged automatically according to the programmed order, then the clamp will grip one layer of product and move them to the basket, and then the interlayer clamp will pick the interlayer and place it into the basket which is on the top of cans. Repeat above actions, load cans layer by layer, once the basket is full, the complete basket will be transported to the retort by chain conveyor, after sterilization, the basket will be transported to unloading system by chain conveyor, and the unloading system will move the cans to the cans conveyor layer by layer. The complete process is manless production, which will improve the production efficiency.

Electrical Configuration:

| PLC |

Siemens |

| Frequency Converter |

Danfoss |

| Photoelectricity Inductor |

SICK |

| Driving Motor |

SEW |

| Pneumatic Components |

SMC |

| LOW-voltage Apparatus |

Schneider |

| Touch Screen |

Weinview |

| Servo |

Weinview |

Technical Parameter:

| Height of cans/bottles |

According to customer's product |

| Max. carrying capacity /layer |

150Kg |

| Max. carrying capacity /basket |

Max 1500kG |

| Max. stack height |

According to the retort basket size |

| Installation Power |

48KW |

| Air Pressure |

≥0.6MPa |

| Power |

380V.50Hz , three-phase |

| Consumption of the Air |

1000L/Min |