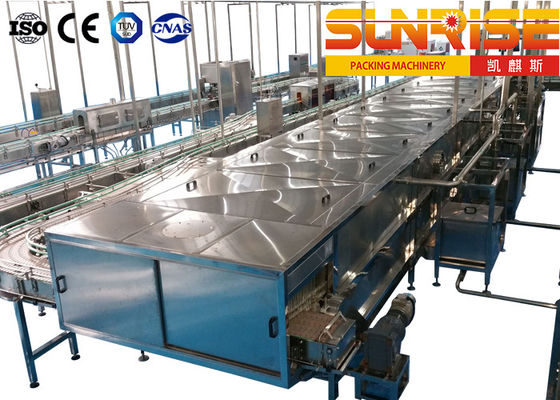

KYSJ00 Sterilizing and cooling Tunnel ,sterilization tunnel for food packaging,Continuously Spraying Type Sterilizing and cooling Tunnel

Product Introduction :

(1) Host module

The overall dimensions of the machine are determined according to the product output and customer process requirements, and the height is determined according to the product height, and the import and export are sealed. The height of the chain net is adjustable from 1000 to 1100, and the running speed of the net belt is adjustable from 0 to 1000 mm/min. The main frame is made of high-quality stainless steel. The spray header on the upper part of the spray adopts industrial grade stainless steel seamless pipe to prevent bursting when the pressure is too high.

Equipped with cleaning manholes and overflow ports to facilitate personnel to enter the equipment to clean and remove equipment residual liquid. The box has a window to observe the production operation.

(2) Steam pipeline

The steam inlet and outlet pipelines are made of sanitary stainless steel seamless pipes to prevent bursting when the pressure is too high. The steam injection holes are arranged with a certain inclination to avoid direct steam injection to the cabinet, reduce noise, and effectively reduce steam overflow.

(3) Heat exchanger

The steam direct injection heating method is adopted, and the steam intake volume is adjusted in real time through the pneumatic film regulating valve to control the water temperature in the heating and heat preservation section of the cabinet.

Sterilizing and cooling Tunnel Product Properties :

| 1. Production capacity: | optional according to customer requirements |

| 2. The height from the chain net of the spray sterilizer to the ground: | H=1050±50mm |

| 3. Rack height: | Determined according to bottle height |

| 4. Frame length: | effective length +1600mm |

| 5. Rack width: | 2000mm |

| 6. Compressed air source: | 0.8Mpa |

| 7. Air consumption: | 0.05m3/min |

![]()

![]()

![]()

(1) Water supply pipeline

The pipeline adopts sanitary stainless steel seamless pipe to prevent bursting when the pressure is too high, and the water tank adopts high-quality SUS304 material. The pump can be selected according to customer requirements, and the pump can be connected to the sump. The nozzle is made of SUS304 stainless steel, the nozzle hole is not blocked, acid and alkali resistance, and high temperature resistance. The nozzles are evenly distributed to ensure that the bottle and the water evenly contact.

Equipped with manual main water supply port and automatic auxiliary water supply port. A float level gauge is installed on the water tank to facilitate automatic level detection and control.

(2) Box insulation layer

High-quality polyurethane insulation layer is arranged in the heating and insulation section of the cabinet. Weld and assemble high-quality stainless steel plates outside the insulation layer.

(3) Control system

Equipped with a control box, touch control panel can display: real-time spray temperature, real-time chain network operating speed, real-time deceleration motor operating frequency and other parameters (optional). It is convenient for workers to control the equipment.